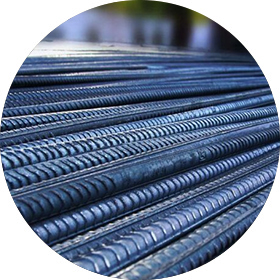

At Mahakal TMX, we manufacture high-performance TMT bars using cutting-edge Thermex technology. Trusted by engineers and contractors nationwide, our bars are built to exceed expectations in strength, ductility, and safety.

The Strength Statement

Build Strong. Build with Mahakal TMX

Engineered TMT bars with superior strength, flexibility, and seismic resistance — made for lasting structures.

The Technology Angle

Thermex Technology. Certified Strength

Mahakal TMX delivers IS 1786:2008 certified TMT bars built with precision and cutting-edge Thermex processing.

The Application-Based Focus

From Homes to High-Rises. We Reinforce It All.

Ideal for residential, commercial, and industrial construction — Mahakal TMX bars are built for every challenge.

A Company Built on Strength and Innovation

Organization & Certifications

Certified under IS 1786:2008 standards, Mahakal TMX is committed to delivering steel that stands the test of time — even in extreme conditions

Projects Completed

MT TMX Delivered

Trusted Dealer

Manufacturing the Future of Construction

Superior Bendability & Weldability

Easily workable for complex designs with high structural integrity

Corrosion & Fire Resistance

Resists rust and high temperatures — ideal for coastal and fire-prone regions

Delivering Strength On Time and On Budget

• Advanced Thermex Processing

• Reliable On-Time Delivery

• Consistent Quality Across Batches

• 24/7 Project Support

- High-Strength TMT Bars

- IS 1786:2008 Certified

- Earthquake Resistant

Engineered for Strength

Thermex-powered TMT bars with high tensile strength and durability for all structural needs.

Engineered for Strength

Thermex-powered TMT bars with high tensile strength and durability for all structural needs.

Timely & Trusted Delivery

On-time dispatch with efficient logistics to keep your project running smoothly.

Timely & Trusted Delivery

On-time dispatch with efficient logistics to keep your project running smoothly.

Optimized for Budget Efficiency

High-quality bars at competitive rates to help you stay within budget.

Optimized for Budget Efficiency

High-quality bars at competitive rates to help you stay within budget.

Reliable Project Support

End-to-end assistance with 24/7 support for orders, delivery, and queries.

Reliable Project Support

End-to-end assistance with 24/7 support for orders, delivery, and queries.

- Corrosion Resistant

- Thermex Technology

- Built for Generations

From sourcing to steel delivery, Mahakal TMX ensures customer satisfaction at every step.

Residential &

Commercial Buildings

High-Rise

Towers

Bridges &

Infrastructure

Industrial

Facilities

Safer Living Spaces

- Earthquake-Resistant TMT Bars

- Superior Concrete Bonding

Designed to protect homes from seismic shocks, Mahakal TMX bars provide unmatched ductility and grip with concrete — ensuring safer and more stable buildings.

Flexible for Modern Design

- Excellent Bendability

- Smooth Weldability

With low carbon content and high flexibility, our TMT bars can be bent and shaped easily — perfect for contemporary architectural designs and compact spaces.

Built to Last

- Corrosion-Resistant

- Certified as per IS 1786:2008

Mahakal TMX steel bars protect your property investment with long-term durability, even in humid or coastal environments.

Load-Bearing Excellence

- Superior Tensile Strength

- Minimal Steel Consumption

Engineered for vertical strength, Mahakal TMX ensures high-rise buildings can bear intense loads without increasing construction material usage.

Safety at Every Floor

- Fire & Heat Resistance

- Uniform Strength with Thermex

Fire safety is critical in tall structures. Our bars are built to resist extreme temperatures while maintaining consistent strength from core to surface.

Precision in Every Inch

- Automated Manufacturing

- Advanced Rib Pattern

Made using advanced Thermex and automated systems, Mahakal TMX offers precision grip and structural balance, making it ideal for complex vertical construction.

Withstand the Elements

- Anti-Corrosive Strength

- Ideal for Coastal Areas

Bridges face constant environmental exposure. Mahakal TMX TMT bars resist rust and environmental wear, ensuring long-term endurance.

Heavy Duty Performance

- High Yield Strength

- Shock Absorption

For highways, overpasses, and flyovers, our bars support immense weight while absorbing impact — reducing structural fatigue over time.

Built for Generations

- Long Lifespan

- Reduced Maintenance Needs

Once installed, Mahakal TMX bars provide decades of performance, minimizing long-term maintenance costs for large-scale projects.

Thermal & Load Resistant

- High Thermal Resistance

- Industrial-Grade Load Capacity

In factories and heavy-use zones, our bars stay strong under intense heat and load, protecting both structure and workforce.

Reliable, Even Under Pressure

- Excellent Weldability

- Uniform Strength Distribution

For large industrial machines and floor load support, Mahakal TMX ensures flawless performance from foundation to roofline.

Smart Investment for Industries

- Lightweight but Durable

- Optimized for Speedy Construction

Reduce material waste and accelerate construction timelines with TMT bars that are lighter in weight but heavy in performance.

Explore Our Recent Projects

Media Tech & Machino Manufacturers have been working together for over 10 years. Their staff is knowledgeable & their response time is prompt.

Nathan Felix

CEO, High Rise Construction

Get swash & Machino Manufacturers have been working together for over 10 years. Their staff is knowledgeable & their response time is prompt.

Mubashir Razi

CEO, High Rise Construction

Sheet bilge & Machino Manufacturers have been working together for over 10 years. Their staff is knowledgeable & their response time is prompt.

Davila Felix

CEO, High Rise ConstructionLatest From Our Blog

- View All

- News

- Press Realease

- Tips & Tricks

Manufacturing Process

-

-

Step 1: Billet Yard

High-quality, low-carbon steel billets are carefully sourced and stored — forming the raw foundation of our superior TMT bars.

-

Step 02: Reheating Furnace

Billets are uniformly heated in a controlled, energy-efficient furnace to achieve the ideal rolling temperature for shaping.

-

Step 03: Rouging Stand

The heated billets are passed through initial rolling stands where they are roughly shaped into preliminary bar forms.

-

Step 04: Inter Mill

Bars undergo secondary rolling for dimension refinement, maintaining consistent thickness and structural balance.

-

Step 05: State-of-the-Art Mill

Precision shaping takes place in a fully automated mill, ensuring exact dimensions, surface finish, and consistent strength across the length of each bar.

-

Step 06: German Thermex

Our bars pass through the advanced German Thermex system, where high-pressure water rapidly cools the outer layer — forming a strong outer shell and soft, ductile core.

-

Step 07: Automatic Cooling Bed

Post-quenching, the bars are slowly air-cooled on an automated bed, allowing for self-tempering and enhanced mechanical properties.

-

Step 08: Finished Product Yard

After final quality checks, the finished TMT bars are bundled, barcoded, and moved to our storage yard, ready for delivery.

-

Step 09: Loading & Dispatch

Using well-coordinated logistics and trained staff, the finished goods are loaded safely and dispatched on-time to project sites across India.